Pye History

1932 - 1946: Keith M. Wrigley

Long before the Waihi Gold Mine closed in 1952, Keith Wrigley had, in 1932, established a radio sales and repair business with a capital of 52 N.Z. pounds (buying in complete radios) in lower Seddon Street, in what came to be called ‘The Dean Building’. He was the elder son of James Wrigley, a reporter on the Waihi Telegraph.

A plaque was placed on the building to mark the event, but this has been removed in later years.

As the business grew, he moved to premises also in Seddon Street where he decided to manufacture his own sets, under the trade names of “Futura”, “Luxur” and “Everest”. This site later became the Waihi Dry Cleaning Co. Each set carried a plate reading “Made by Keith Wrigley”.

At this stage he decided to manufacture components as well, so he moved to a vacant dairy in Rosemont Road, next door to E. A. Clark pharmacy. In January 1938 he moved again to a two storey building in Upper Seddon Street close to the Anglican Church. This building later became Attwood Aluminium. By 1937 Wrigley formed “Akrad Radio Corporation” and was now employing 50 staff producing a wide range of radios and appliances, including electric fences. When war broke out in 1939 (second world war), he was still producing radios but by 1942 the government decreed “this had to cease”– “ and he make radio equipment for the services”. This required larger premises so, in 1943 he moved into the King’s Hall in Haszard Street.

Here they began work manufacturing signalling lamps, morse sets, buzzers, air raid sirens, radio components (coils and transformers) and battery adaptors.

Unofficially a small run (3 or 4), 12 volt battery operated domestic radios were made and delivered to the U.S. army in Auckland.

By 1945 the work force had grown to 90. As the acquisition of components became uncertain, Mr Wrigley introduced a new line, children’s tricycles. “The Akrad Flyer” reached its peak in 1947 when the 50,000th trike rolled off the line , and a few years later a total of 180,000 had been made.

The large Akrad Flyer below was made as a one-off to be used on special occasions. It is now held by the Waihi Museum and is ridden in the Christmas parade from the old factory (now Waihi Gold H.Q.) up the main street and back again. The smaller model in the picture is a standard production run.

When the line was finally closed in 1969, about 200,000 had been made and Tonka Toys then bought that part of the business, running it for 5 years. In 1974 the “Akrad Flyer’ returned to Waihi when Brown and Brown (Waihi) took over production for a further 10 years. Both firms had made about 10,000 trikes a year, so from 1945 to 1984 approximately 300,000 “Akrad Flyers” had been turned out.

Unfortunately on New Year’s day 1946 Mr Wrigley died suddenly, from osteomyelitis, at the age of 33, ending a 14 year development of Akrad.

1946 - 1947: G. A. Wooller

At this stage Akrad was in considerable financial difficulties through having to meet death duties and income tax.

George Wooller had been production manager at Radio Ltd, Auckland, and had been in this position for the duration of the war. This association led to George Wooller forming G. A. Wooller and Co., acting as a distributing company for Akrad manufactured products and this in turn had a profound effect on the post war growth of Akrad.

Under Keith Wrigley’s will, a company was formed under the direction of the Public Trustee. As they had no knowledge of radio manufacturing, they called on George Wooller and Mr Moore Haszard (along with W. Leitch and W. Meiklejohn.) to manage Akrad through this difficult period.

1947 - 1957 (approx): T. J. F. Spencer

In 1947 Tom Spencer was appointed manager and ‘Akrad Radio Corporation Ltd.’ was formed with a capital of 30,000 pounds. This put Akrad on a firm financial footing. In 1948 Mr Spencer was made managing director. Prototypes of motor scooters and a trial run of 50 rotary lawn mowers (the first in New Zealand) were introduced. A trial run of kit-set refrigerators imported from Australia and assembled here were also tried, but these innovations were shelved as the directors felt they were not the company’s prime objective.

A chain of Akrad dealers was set up to sell the radio products - small portable radios to large cabinet models, under the brand names of “Pacific”, “Regent” and “Five Star”.

In 1947, Green and Cooper who were the New Zealand agents for Pye (U.K.) VHF radio-telephones, supplying Auckland Traffic Department, followed by Auckland Fire Brigade. Then Wellington Taxis were supplied with 30 VHF units made in the Waihi factory. By 1962 Pye was the leading manufacturer of radio-telephones in New Zealand, the sets being produced both in Waihi and Wellington.

By 1949 with the world wide growth of T/V the directors felt it would be best to be associated with an overseas company, so an approach was made to Pye Ltd, Cambridge, England.

Mr C.O. Stanley (chairman of Pye U.K.) came to New Zealand for negotiations.

Pye (N.Z.) Ltd was set up in 1951 and Mr G. A. Wooller was appointed Managing Director. By 1952 Pye U.K. had a substantial shareholding in Akrad which led to an increased expansion of the company.

Mr Ted Grant, who joined the firm in 1940, became the chief engineer in charge of the “Lab” at Barry Road where 20 engineers and draftsmen (and ladies) were now employed. As the product range increased and the staff had increased to 31, room for more Research and Development space was required . The ‘Lab” was doubled in size in the 1960s.

Television was getting established and when Queen Elizabeth II came to N.Z. in 1953/4 Pye brought in a T/V rack mounted transmitter and cameras from Pye UK to cover the Queen’s dinner in the Wellington town hall. The system was operated by Pye UK engineers except for the audio side, which Ted Grant operated. Other smaller demonstrations were also staged at that time. The equipment remained the only unit of its kind in the country for several years.

The first outside T/V broadcast of a rugby match, staged by Pye engineers at Waihi Rugby Park in 1954, was the game between Harlequins and Barbarians; the pictures and commentary (using the same system as above) being transmitted to some 100 Pye T/V sets round the ground, Waihi Hospital and several private homes. Ted Grant, Ken Tribble and Trevor Corder operated the “control room ”.

At the 1954 Auckland Easter Show, a T/V studio was built, with telecasts transmitted to Pye sets in Green Lane Hospital and several private homes. Pye Waihi provided engineers to operate and supervise the equipment. Using the rack mounted equipment and cameras, several demonstrations were organised for dealers, plus a few hospital operations were covered on CCTV, Ted Grant being the camera man.

In 1955 a further reconstruction of the Pye group in New Zealand took place when G.A.Wooller and Co. Ltd and Green and Cooper Ltd were both absorbed into the group and the company changed its name to Pye Ltd; Akrad remaining the group’s principle manufacturing unit.

1958 - 1960: G. Rowe

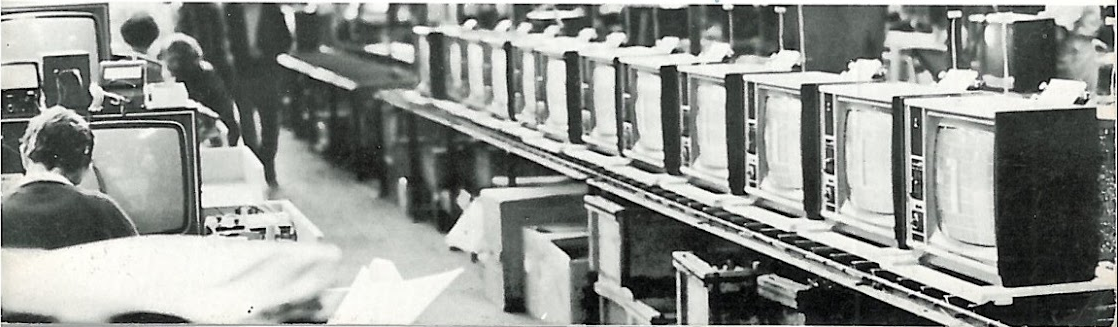

Production of Pye designed black and white television sets began in July 1959 at the rate of 10 a day. 300 of the 21inch model 201T were made for closed circuit T/V in Auckland as transmission of T/V had not started in New Zealand.

By 1962, T/V transmission in parts of New Zealand had begun. 10,000 various models were produced annually and by 1966 over 150,000 had come off the line, after two “soak tests” of more than eight hours. In 1965 Mr Graham Street was in charge of T/V production, taking over from Mr Barry Babbage.

Demand for Pye products grew even more, so production had to keep pace. The Waihi work force in 1982 stood at 405 at No. 1 and 2 plants (more women being employed than men) with 75 employed in Paeroa and 31 at the Barry Road Lab. In all, nation wide, Pye employed almost 1500, including a depot in Christchurch.

Quality control of all Pye’s products was becoming more important and as a result a new section was introduced to cover this area with Mr Laurie Horton to manage it; he also became factory manager in 1981 to 1982.

1960 - 1981: R. Skinner

From 1960, Mr Ron Skinner was factory manager, Mr Henry Jensen production manager, Mr Ross Vickery in charge of the machine shop (Mr Lyall Bowen took over in 1979) and Mr Henk Bouius was running the tool room. Mr Arthur Lindsey (Artie) was head of the King’s Hall winding and coil section. Also in King’s Hall, Mr Murray Radford was looking after the trike line, the relay line and the speaker department.

In 1962 Pye Waihi manufactured 26inch black and white T/Vs and between 1962 and 1977, 250,000 sets had been made. Colour T/V came on the scene in 1972. Production of the first Pye colour set designed under Mr Ken Trible’s guidance, using printed circuit boards (PCBs) commenced with a small run of 100 units. Ken soon developed a system to mount the PCBs vertically, thus reducing the depth of a T/V cabinet by 76mms. Pye was first to use the 26inch Toshiba In Line Gun colour tube, before Japan.

By 1962 the company had grown to include:- Pye Electronics Ltd, G. A. Wooller & Co Ltd., Green & Cooper Ltd., Radio Corporation of N.Z. Ltd., International Records Ltd. as well as the Akrad Radio Corporation Ltd. Two factories were opened in Paeroa: Pye Records and the “Winding Room” making transformers , coils and runs of small portable radios.

In 1960/1 Pye U.K. invested 1 million pounds in a massive up-grade of the Waihi factory. A new machine shop, plating , paint shops and tool room were built alongside the King’s Hall (No 1 plant) ; the main assembly, office and cafeteria seating 200, (No 2 plant), went up in Moresby Avenue, opening in December 1962 and the Research and Development Laboratory in Barry Road was constructed.

Now the work force had grown to 200, with staff commuting from Katikati, Waihi Beach, Paeroa and Whangamata. Pye N.Z. was spreading its wings over the North Island. In Auckland the head office was set up, with Pye Consumer products, Pye Telecommunications and Industrial Electronics. Near Hamilton at Te Rapa, Audio Products including Akai reel-to-reel and cassette recorders plus their “Dolby” systems (under licence) were manufactured. Development of these products took place in Waihi. At Frankton, Cabinet Productions was set up. In the early 1970s, another first was being used in the cabinet factory, a precision wood cutting machine, made in the Pye tool room. This could cut a 90 degree slot in the material leaving a fraction of a millimetre, without breaking through. It cut three V slots and a 45 degree cut on each end, so with glue added to these slots and ends the sheet was then bent in another machine which also applied the glue, to form the top, bottom and sides of the cabinet; it then only needed a front and back. The Frankton factory also made coffins. Moving south to Wellington, Wire & Cables was born, and R.C.A. records came under Pye control. Thus many of the products required to produce both radio, T/V and consumer goods were “in house”

Dick (Richard) Bing began work with Pye NZ in Waihi in 1964 having worked for Pye in Britain in a range of roles. His time in Waihi was to see him employed in the factory on fault repair, in the relay department designing radio and HiFi units, in the Lab in Barry Road, managing the instrument section and then quality control. All up he was with Pye/Phillips (who took over Pye) for 38 years.

A production line to produce relays was set up in the ‘60s; Pye U.K. had been making relays for some time under the name “Magnetic Devices “ so most mechanical parts were imported but the coils were wound here. The main production was the ripple control relay for the Power Board, 800 were produced a week. Small runs (50 or 100) would be made to special order for other types of relay.

In 1966, Waihi had a festival week called “Mardi Gras”. Outside the Memorial Hall an ‘Igloo’ was set up (thanks to Mr Erny Hands) and Jim Gurney (a Pye employee) lived in it for the week. Jim operated a sound system, installed by Pye engineers, to cover part of Seddon Street and Rosemont Road.

This led to the concept of a sound system to cover the centre of town; the first in the Country. Pye donated the materials, which included two kilometres of cable and thirty speakers with transformers, cabinets and grills. Pye engineers, with help from The Chamber of Commerce, did the installation.

In 1966, Mr Dick Spurr was in charge of the silk screen room and in 1971 the first printed circuit boards (PCBs) were made. This eliminated the tangle of connecting wires. The first material was copper-clad fibre glass. At first these could not be punched without board damage, so they had to be hand drilled. Later a method was found to punch all the component holes in one operation.

To produce the boards, first a map of the tracks with etch resist was put on the copper side using silk screening, then the unwanted copper was etched away. This was labour intensive and time consuming . The boards had to be put into stainless steel racks, then into a hot agitated solution of ammonium persulphate and took about 5 minutes per batch to etch. They were then washed, the resist stripped off , washed again, then dried ready for punching. About this period transistors had been developed and incorporated into design and production of radio sets using PCBs. Pye was the first manufacturer to market them in N.Z. under the brands of “Ultimate”, “Astor”, Ultimate-Ekco” as well as “Pye”.

In 1971, a spray etch machine using Oxytron 21 {replacing the ammonium persulphate } was purchased ( the first in N.Z.). The boards then came out in a continuous stream. Only two operators were required for this process as board handling was reduced to a minimum. Silk screened boards were fed in at one end of the machine and the finished boards came out the other, dry and ready to be punched with holes for the components.

The use of the flow soldering machine meant that the printed circuit boards were held in a cradle after all the components were put in place and all were soldered in one go when the board was moved across the solder surface. This saved a lot of time as each component had to be soldered by hand prior to the machine being installed.

1972 saw the board base material change to copper-clad bakalite, though fibre glass was still used for special work. The tool room was the section of the plant where punch and die sets to go in the presses were made, as well as specialised tools for production. About this time Mr Ben Foster was in charge of the technical side of radio production.

Colour T/V production soon grew - Pye producing three more models, CT101, CT102 and CT103. As well as supplying the home market, sets were being exported to Hong Kong. The first batch, sent in 1977, being able to compete against European and Japanese competitors.

In 1977, Pye came up with another “first”, a three year guarantee on parts and labour on all their sets. Later, in 1978 Pye was exporting the latest colour T/V CT104 [ a single vertical printed circuit board set ] to :- Singapore, Malaysia, Sri Lanka, Brunei, Fiji and China, as well as Hong Kong. Fifty percent of the colour T/V production was being exported. In 1979 Mr Ken Tribble and Mr Grahan Street went over to China to negotiate with production staff at the No 1 T/V factory in Shanghai. The aim was for them to produce 1,000,000 CT104 T/Vs per year under licence, with the royalties going to Pye N.Z. But at this time Philips had taken over Pye U.K. and they did not want competition in China, so the arrangement was squashed. This would have been another first for Pye.

1981 - 1982: L. Horton

In late 1967, the Dutch organisation Philips had taken control of the parent company,( Pye U.K.) and by 1981 Pye Waihi had come under their influence making audio equipment using their name.

1982 - 1983: J. Foster

Philips re-organised the No.2 production floor in 1981/2 holiday period but later took T/V production to their plant in Naenae near Wellington; this was to make space and to concentrate on audio production in Waihi.

1983 - 1986: R. Evans

Philips had said several times that the Pye Waihi factory would not close. However when the Government removed the import duty on Asian goods, Pye and all other major electronic factories in New Zealand could not compete on price and had to close.

Pye had been a world wide organisation, having established numerous factories in the U.K., Eire, Canada, Australia and New Zealand. Thus in September 1986 a 55 year era of electronics (started in Waihi by 18 year old Keith Wrigley, under the name of “Akrad”) came to a sad end.

Footnote :- On 26th September 1986, Mr Graham Street placed a time capsule in No 2 plant.